| 268 Heping Street, Zaoqiang County, Hebei Province, China. – Anping County – China, Bohai Bay | +86-318-75820056 | |

| www.coolingtowerfills.com | ||

Cooling tower herringbone fill is designed with herringbone surface to distribute water evenly over the whole fill area for high thermal performance. This media has specific surface design and moderate anti-fouling tendencies, fabricated from rigid PVC or PP sheets that are solvent welded for maximum strength. HPVC is also available for high temperature conditions. It is used in cross-flow cooling tower applications.

There is one piece of black cooling tower fill on the ground.

We offer different sizes of herringbone fills for cooling tower, and the surface configuration may vary from each other.There is one blue cooling tower herringbone fill on the ground.

Blue cooling tower herringbone fills are also available for some cooling towers.

There are many pieces of herringbone fills piled together on the ground, and you can see the surface configuration clearly.

Cooling tower herringbone fills are just made from the factory, and the herringbone design on the surface contributes to even water distribution.There is one black cooling tower herringbone fill on the ground.

Cooling tower herringbone fill in black is commonly used, and the size shall be made by the cooling tower dimension.

There is one piece of black herringbone fill for cross flow cooling towers.

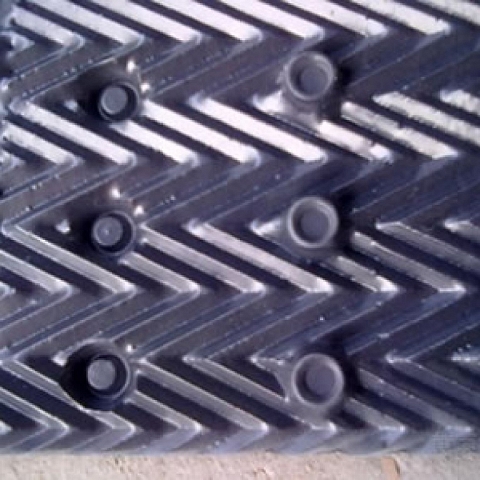

Apart from herringbone surface design, cross flow herringbone fill has other properties varying from each other according to different cooling towers.The picture shows detail of one cooling tower herringbone fill.

Herringbone surface design makes large quantities of "w" shaped flutes, which distributes water evenly over the entire fill area.

Feature

Excellent air & water management for high thermal performance.

Herringbone surface design maximizes heat transfer for even water distribution.

Honeycomb bonded edges on the air inlets and outlets.

Resistant to UV, corrosion, organic/inorganic solvents, acids, alkali, etc.

Various sizes and sheet spacing for choice.

Easy installation and maintenance.

Specification

Material: PP, PVC, HPVC.

Surface area: 167.4 m2/m3.

Sheet spacing: 19 mm.

Media pack sizes:

Depth: 305-610 mm.

Width: 153-305 mm.

Length: 610-3658 mm.

Application

Cooling tower herringbone fills are suitable for cross flow towers, mainly in air-conditioning cooling water system, iron and steel industry, paper making, pharmacy, etc.

Ransen Cooling Tower Fills Factory

Activity: Ransen Cooling Tower Fills Factory

Welcome to our website for choosing one suitable cooling tower fill. Here you will find replacement parts for almost any models of cooling towers varying from small type to large-scale. We are aiming to fulfill all requirements for your specific project. As a professional cooling tower fills supplier, Ransen cooling tower fills factory is engaged in catering to ever changing demands of customers by bringing forth utmost quality fills made from PVC, PP, HPVC, etc. There are four kinds of cooling tower fills on the picture, and they have different profiles and colours. How many types of cooling tower fills we offer? We offer you a wide range of cooling tower fills with different configurations and dimensions, the main products are as follows: round cooling tower fills, cooling tower vertical fills, offset fluted fills, cooling tower herringbone fill, cross fluted cooling tower fills, s wave cooling tower fills and special cooling tower fills. What makes us unique? Quality products with various configurations Quality is the core of an enterprise running, and we have been following the principle of "quality first, prestige first" since we opened our business. All of our fills are weather resistance and insusceptible to chemical degradation. Various configurations are made to fit different types and models of cooling towers. Direct supply from factory All of our fills use the most reliable raw material of PVC, PP, and manufactured from factory directly, which ensures them to enter the market with a competitive price. It means cost budgeting is also taken into consideration by us. Hands-on approach of cooling tower experts Our engineers works closely with any customer throughout the design, engineering and manufacturing process of each cooling tower project. To achieve the most cost saving and efficient cooling effect, our experts with rich experience always have completed solutions. We have gained utmost customer satisfaction with our efficient service since establishment. Free sample and prompt delivery Our factory is located with advantage of convenient traffic and quick logistics, which could guarantee prompt delivery of products. Free sample is also available if you are interested in our cooling tower fill media, contact us for more details! We are looking forward to cooperate with you for further cost-effective solution for cooling towers, send us email or call us. Happy to answer any questions you many have and assist you with any of your cooling tower needs.